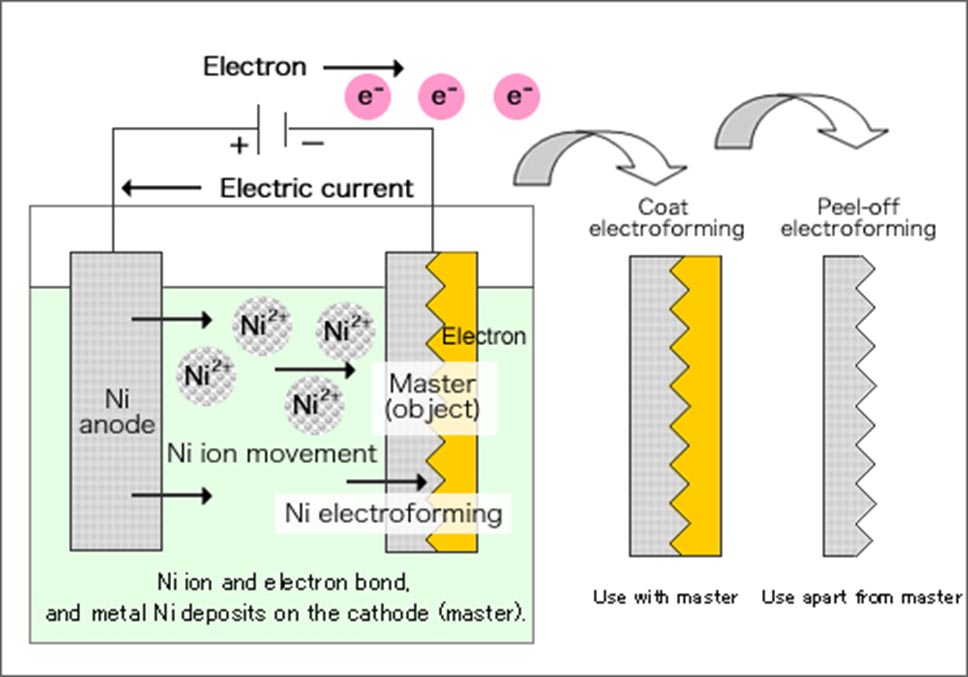

1) Electroforming stencil

Iyo yekugadzira nheyo ye electroformed stencil: iyo electroformed template inogadzirwa nekudhinda iyo photoresist zvinhu pane conductive simbi base ndiro, uye ipapo kuburikidza masking mold uye ultraviolet exposure, uye ipapo mutete template ari electroformed ari electroforming mvura.Kutaura zvazviri, electroforming yakafanana ne electroplating, kunze kwekuti nickel sheet mushure me electroforming inogona kubviswa kubva pasi peplate kuti iite stencil.

Electroforming stencil ine maitiro anotevera: hapana kushushikana mukati mesimbi yesimbi, gomba rusvingo rwakanyanya kutsetseka, iyo stencil inogona kuva chero ukobvu (mukati me0.2mm, inodzorwa neiyo electroforming nguva), iyo yakashata ndeyekuti mutengo wakakwira.Iyi inotevera nhamba inofananidzwa yelaser simbi mesh uye electroformed simbi mesh madziro.Iyo yakatsetseka yegomba madziro e electroformed simbi mesh ine zvirinani dhizaini mhedzisiro mushure mekudhinda, kuitira kuti reshiyo yekuvhura inogona kunge yakaderera se0.5.

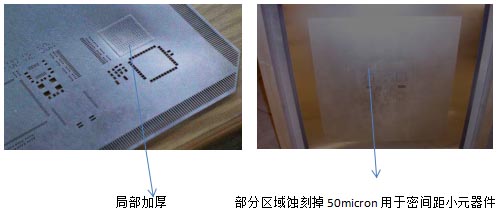

2) Ladder stencil

Simbi yakatsikwa mesh inogona kukobvurwa munharaunda kana kutetepa.Chikamu chakakora chikamu chinoshandiswa kudhinda ma solder pads anoda huwandu hukuru hwe solder paste, uye chikamu chakakora chinowanikwa ne electroforming, uye mutengo wakakwira.Iko kuonda kunowanikwa nemakemikari etching.Iyo yakatetepa chikamu chinoshandiswa kudhinda mapadhi e miniaturized components, izvo zvinoita kuti demolding effect ive nani.Vashandisi vanonyanya kukoshesa mari vanokurudzirwa kushandisa kemikari etching, iyo yakachipa.

3) Nano Ultra Coating

Kupfekedza kana kupfekedza dhizaini ye nano-coating pamusoro pesimbi mesh, iyo nano-coating inoita kuti gomba madziro adzore solder paste, saka iyo yekudhirowa mhedzisiro iri nani, uye kugadzikana kwevhoriyamu ye solder paste kudhinda kunowedzera kuenderana.Nenzira iyi, hutano hwekudhinda hunosimbiswa, uye nhamba yekuchenesa nekupukuta mesh yesimbi inogonawo kuderedzwa.Parizvino, maitiro mazhinji epamba anongoshandisa dhizaini ye nano-coating, uye mhedzisiro yacho inopera simba mushure meimwe nhamba yekudhinda.Iko kune nano-coatings yakanyatsoputirwa pane mesh yesimbi, iyo ine mhedzisiro iri nani uye kusimba, uye zvechokwadi mutengo wakakwira.

3. Double solder namira kuumba muitiro.

1) Kudhinda/Kudhinda

Michina miviri yekudhinda inoshandiswa kudhinda nekugadzira solder paste.Yekutanga inoshandisa yakajairwa stencil kudhinda mapedhi ezvikamu zvidiki zvine pitch yakanaka, uye yechipiri inoshandisa 3D stencil kana nhanho stencil kudhinda mapadhi ezvikamu zvakakura.

Iyi nzira inoda michina miviri yokudhinda, uye mutengo we stencil wakakwirawo.Kana 3D stencil yakashandiswa, comb scraper inodiwa, iyo inowedzera mari uye kubudirira kwekugadzirwa kwakaderera zvakare.

2) Kudhinda/kupfapfaidza tin

Yekutanga solder paste printer inodhinda pedyo-pitch madiki echikamu mapedhi, uye yechipiri inkjet printer inodhinda mapedhi makuru echikamu.Nenzira iyi, solder paste molding effect yakanaka, asi mutengo wakakwirira uye kushanda kwakaderera (zvichienderana nehuwandu hwezvikamu zvakakura).

Vashandisi vanogona kusarudza kushandisa mhinduro dzinoverengeka dziri pamusoro zvichienderana nemamiriro avo.Panyaya yemutengo uye kubudirira kwekugadzira, kuderedza kukora kweiyo stencil, uchishandisa yakaderera-inoda aperture area ratio stencils, uye nhanho stencils ndiyo yakanyanya kufanirwa sarudzo;vashandisi vane yakaderera goho, zvemhando yepamusoro zvinodiwa, uye vasingadhuri vashandisi vanogona kusarudza kudhinda/jet kudhinda Chirongwa.

Nguva yekutumira: Aug-07-2020